Folding Cartons

Using the BSR Rotary Diecutter Inline or Offline

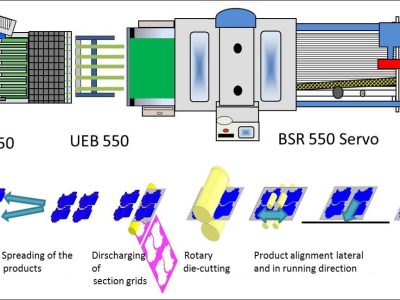

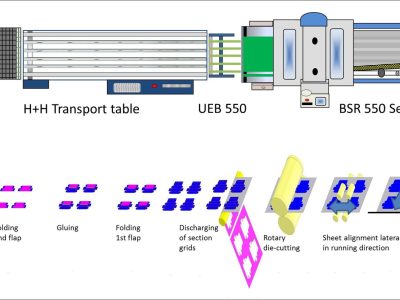

This solution from MBO America allows end users to produce folding cartons inline at very high speeds. The BSR 550 Servo rotary die cutter is able to cut product without leaving any nicks or holding tabs – this means that the waste matrix can be removed inline at high speeds. Once the waste matrix is removed, a series of plowfolds and gluing are all that is needed to finish the job. The 091.1 Mailing Table is compatible with hot glue and cold glue applications and can easily be mounted with additional equipment for more complex applications including tipping and window patching. Because of the short setup times, MBO’s 2-Up Folding Carton Solution is highly recommended for short – medium length job runs.

Features and Benefits

- Cutting, scoring, perforating, embossing, and braille are all possible with the BSR 550 Servo rotary die cutter.

- The 091 Mailing Table can be equipped to produce as many as 4 functions in sequence

- Hot melt and cold glue systems are both readily available

- Speed synchronization ensures that speed adjustments made at one unit will be matched by the other units.

- Cutting without holding nicks in combination with the Automated Waste Removal System eliminates the need for manual production steps to remove waste

This Solution Generally Consists of:

- BSR 550 Servo Rotary Die Cutter

- UEB 550 Stripping Unit

- Various Deliveries

- Can be integrated as an inline with the folder gluer using MBO’s 091 Vacuum Plow Table

Image Gallery

Technical Specifications

MBO High-Speed Folding Cartons

Two Module Folding Carton Production System