Quantum Graphics Bundles New Komori GL advance Press and MBO T800.1 Buckle Folder to Significantly Enhance Productivity.

Quantum Graphics Bundles New Komori GL advance Press and MBO T800.1 Buckle Folder to Significantly Enhance Productivity.

Rolling Meadows, IL, September 19, 2023

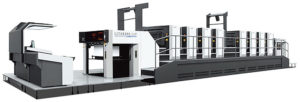

Komori America announced today that Quantum Graphics, a commercial printer based in Eden Prairie, Minnesota, is looking forward to gaining a higher level of automation and faster speed to market with the investment in its fourth Komori press, an eight-color Lithrone G40 advance perfector (GL840P advance) with LED-UV and an MBO T800.1 buckle folder. Experiencing substantial growth over the past several years, the company services well-known brands that demand high-quality, consistent color and fast turnaround. The GL840P advance’s ability to deliver high-speed production coupled with the MBO T800.1’s automated functions will provide the increased capacity needed to meet Quantum Graphics’ aggressive demand forecast.

“To meet our goals, we needed to update our equipment,” said Guy Peterson, president and CEO of Quantum Graphics. “As part of the process, we decided on the eight-color perfector because it would give us additional capabilities and greater capacity beyond our current offering. The press configuration is well-matched to the variety of work we already produce for our clients and will allow us to offer new inline embellishment and coating effects to add additional value to client projects. We anticipate the GL840P advance will double our throughput, which made adding a folder with the automated features of the T800.1 a must. Another key driver in choosing the GL840P advance was paper savings. Our analysis showed that the automation tools in the press to expedite job changeover and makeready will allow us to substantially reduce the amount of paper needed to get to color and cut production time in half. This will increase our speed to market and reduce costly setup waste, saving money and resources.”

The new press is slated for installation this November, while the MBO T800.1 is already on Quantum Graphics’ floor, delivering the benefits of its advanced automation that gets jobs on and off the machine faster for maximum productivity. “Beyond the simple addition of more folding capacity, one of the biggest benefits for us with the T800.1 is its automated setup process, especially for double gate folds,” said Peterson. “With this feature, we can go from an approximate two-hour setup time to just 45 minutes.”

The ease of use both machines offer was also a deciding factor in the company’s investment as Quantum Graphics promotes its press operators from within. Both the GL840P advance and the T800.1 offer easy-to-learn controls that make training new operators a faster process. Additionally, having the LED-UV capability on the press makes it possible for print projects to deliver off the press completely cured. When the high output of the T800.1 is added to that, Quantum Graphics is looking forward to the time and cost advantages of having a seamlessly integrated printing production system.

“Komori’s mission is to be a true solution provider and support our customers in achieving productivity improvement,” said Lance Martin, vice president of marketing for Komori America and MBO America. “We are excited to see that Quantum Graphics will experience both expanded capacity and cost-saving solutions due to the efficiencies the Komori GL840P advance press and the MBO T800.1 folder bring when working together as a powerful system.”