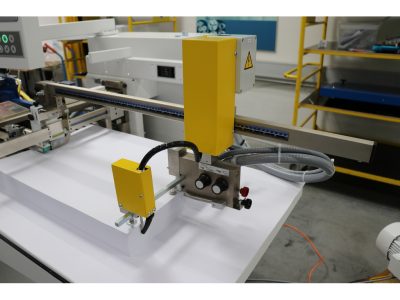

T50 Buckle Folder

The T50 is MBO’s high quality folder for the B2 sheet size. Featuring the high productivity elements from the larger format machines, the T50 is made for fast make-ready and high productivity for long and short runs alike. It is available as an economical manual function machine, or as an automated machine including movement of all buckle plate settings and fold roller calipers for lower make-ready times. MBO’s quick change slitter shaft cassettes allow quick loading and quick adjustment of tooling such as perf wheels and scoring wheels; and even have pre-set tooling kits for repeat jobs. The M1 control system has a user friendly graphical interface; just a few selections from the operator allows the machine to begin make-ready itself. Things like MBO’s high-speed cone guides and larger drive system give it a top end speed of 230 m/m matching our core folding line speed. This feature rich package makes the T50 the ideal folding machine for B2 sizes.

Highlights:

- Short makereadies due to an integrated automation package

- Fast tooling setups using MBO’s slitter shaft cassette technology

- Easy adjustments through MBO’s M1 controls platform, enhances operator capability for higher productivity

- Small footprint even with many feeder, fold plate, and delivery choices

- Reliability and elevated machine uptime thanks to long service life and durability

- 230 m/m (9055 ipm) running speed for the highest in sheet folding productivity

Features:

- Choice of Continuous or Pile feeder to match the application

- Small sheet size capability, 10.5cm x 10.5cm (4.12″ x 4.12″), for pile fed version

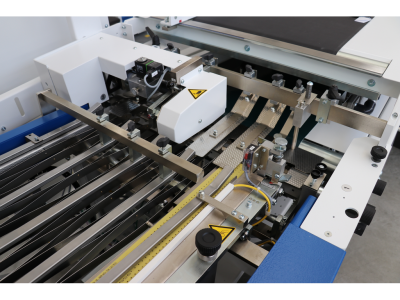

- MBO exclusive VIVAS vacuum infeed and side guide for enhanced sheet control and production speed

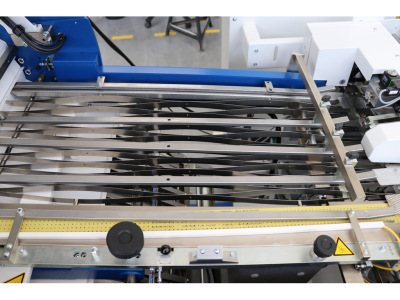

- Anti-static lattice-type alignment table for consistent feeding in first fold unit

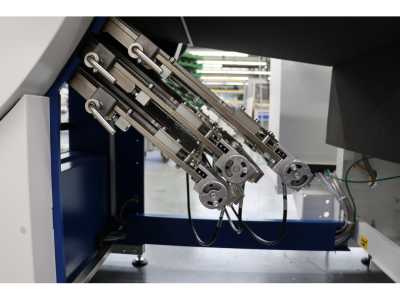

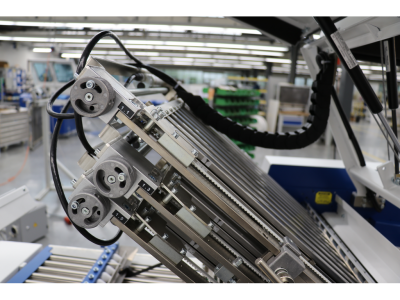

- MBO exclusive high speed cone guide rail in second folding unit for higher transfer speeds and productivity

- 4 or 6 plate folding configurations to suit application

- MBO exclusive low maintenance and low noise belt drive

- Fold rollers with MBO Virotec roller covering for optimum paper handling

- User friendly, graphical, M1 controls interface for fast makeready

- Slitter shaft cassette in the main parallel unit for fast tooling setups

- Scoring, perforating and cutting devices for common jobs

- RAS (Remote Access Service) remote maintenance connection for M1 controls

- Interface connection to MBO M1 DataManager 4.0 System

Alternative Features:

- MBO exclusive VACUSTAR feeder head for enhanced feeder performance

- Slitter shaft cassette for folding unit II

- Noise-damping device for a more comfortable working environment and hearing safety

- MBO gatefold plate for additional fold patterns

- Glue devices added to the folding sections for specialty work

- Double stream device for 2 up production and higher productivity

- X-Knife folding unit for positions II or III for additional fold patterns

- Gutter trim, edge trim, multiple perf, punch perf and other tooling to eliminate secondary operations

Image Gallery

Technical Specifications

Request Info