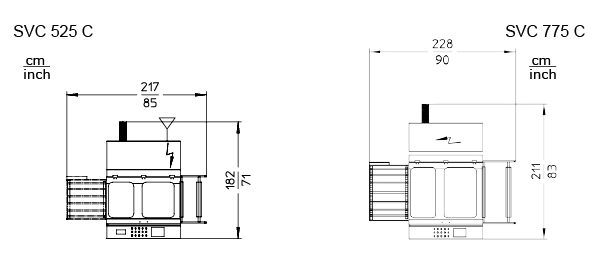

SVC 775 C Sheeter (30")

Overview:

The SVC 775 C sheeter is the heart of the web finishing line from MBO. This servo driven sheeter is engineered to provide high quality precision cuts for a broad range of products at high speeds. Operator setup and interaction is done through a convenient touchscreen control panel. Cut length, mark scanning offset, chipout settings and other functions are programmable allowing for fast, tool-less setup. As with all MBO products, the SVC 775 C’s robust components are built to withstand continuous use in a 24/7 commercial print environment. The SVC sheeter is a modular component and can accept a web from many upstream devices, and deliver sheets to a wide range of modular downstream components.

Features and Benefits:

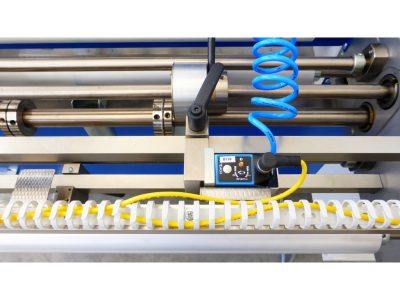

- Tight web, continuous driven roller path at infeed for superior web control

- Easy to use, touch screen user interface panel on operator side

- Large variable cutoff length range 4″-80″, for a wide range of final products

- Memory for hundreds of jobs for recall makeready of repeat business

- Integrated unit converter (inches/mm)

- Infeed web assembly with driven rollers and shafts to guide the web into the sheeter

- Infeed edge trim shafts with ejection tubes facing downward to be connected to the Customer’s waste evacuation system

- Highly accurate, closed loop circumferential register control, +/- 0.010”

- Register scanner assembly mounted on the infeed using a print mark on the web to keep the cuts accurately registered to the print

- Window view function to read a print to cut register mark within a busy print area

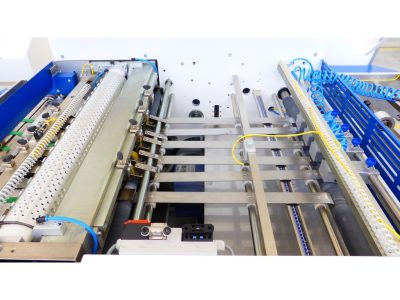

- Dual cylinder cutting design allows sheeting with, or without, a chip-out at the push of a button

- Programmable chip out settings using the touchscreen HMI, allows removal of spit bars, print marks or bleeds

- Waste chip evacuation chute conveniently located on the drive side of the sheeter for connection to customer-supplied vacuum system

- Top and bottom, belt driven exit assembly to pull the cut sheets away from the sheeting cylinders and speed up the sheet to create a gap after the cut

- Swing down capability on exit assembly allows for the ejection of sheets during start-up and open access to clear jams quickly

- Air supported paper flow to achieve controlled sheet transport

- Quick change, durable, long life, square sheeting knives

- Register mark detection capable from top or bottom side of web

- Transformer 208V to 400V Transformer included for USA power requirements

- Built in control interface connection to downstream modules