PP300 Belt Pressing Unit

Overview:

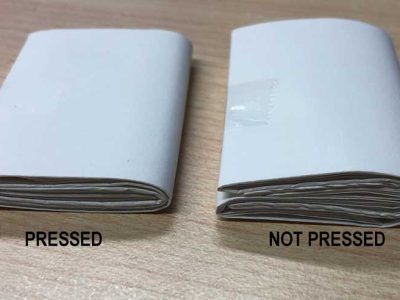

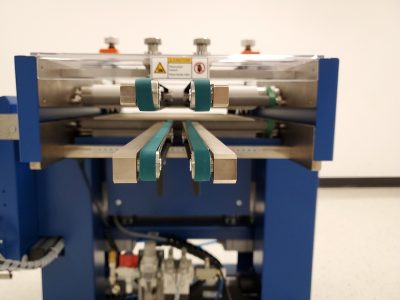

The PP 300 is a module designed to uniquely remove air and flatten pharmaceutical inserts and outserts. The folded product gets forced between two constant speed belts on a roller train that continually presses the product over a long distance. This adds dwell time to the pressing process and eliminates the shock and bounce of traditional systems. The result is a flatter, thinner product with better visuals, more pieces in the tray, and better folding functionality for an increased production rates. Further on the packaging lines at the pharma plant run better when they are fed a flatter, higher quality insert. The unit is mobile and height adjustable so it can be placed in nearly any finishing line.

Highlights:

- Infeed width up to 320 mm (12.5”) for applications with pharma inserts and outserts and beyond

- Belt pressing length approximately 700mm (27”) for increased dwell time to secure the folds

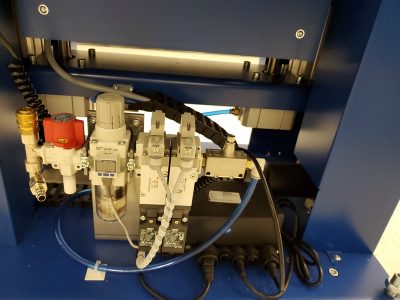

- Large pneumatic pressing power of up to 8000 N (2000lbf)

- Max belt linear speed of up to 60 m/min

- Adjustable working height range from 600-900 mm (23.6” – 35.4”) to fit into nearly any finishing line

- Electric motor assisted height adjustment to eliminate worker stress

- Open access between the pressing belts to easily set up new products and clear jams

- Adjustable mounting foot to account for uneven floors

- Power: 230V / 16A

- Standard MBO 24 pin interface connection with self-drive for flexible applications

- HP Air: 6 bar by customer

- Durable, 24/7 design to take the aggressive nature of pharmaceutical insert/outsert production

Image Gallery

Technical Specifications

MBO PHARMA INSERT SAMPLE WITH GLUE CLOSURE ON THE KL112.1

HERZOG+HEYMANN AND MBO AT DRUPA 2016: OUTSERT LINE