The Art of Die Cutting and Its Role in Print Finishing

The Art of Die Cutting and Its Role in Print Finishing

Die cutting is a crucial technique in the world of print finishing, allowing designers and printers to create intricate shapes and patterns that add depth and visual interest to printed materials. By cutting through paper, cardstock, or other substrates with precision, die cutting transforms ordinary print projects into standout pieces. Whether for packaging, promotional materials, or invitations, die cutting plays a vital role in elevating the overall quality and appeal of print products.

The Basics of Die Cutting

Die cutting involves the use of specialized tools, known as dies, to cut specific shapes from a variety of materials. These dies are typically made from metal and are designed to match the exact dimensions and contours required for the project. The process itself can be done using a variety of machines, ranging from manual to fully automated systems.

Types of Dies Used in Die Cutting

- Flatbed Dies: These are the most common type and are ideal for extremely high volume production without frequent makeready.

- Rotary Dies: These are used in high-volume production runs and are also well suited for quick and efficient makereadies. Applications from gaming and playing card production, to light packaging, and tag and label are very common.

- Laser Dies: These utilize laser technology to cut intricate designs with extreme precision and are often used for specialized projects.

Benefits of Die Cutting in Print Finishing

- Consistency and Precision: Die cutting ensures that each piece is cut exactly the same, providing a uniform and professional finish.

- Versatility: It can be used on a wide range of materials, making it suitable for everything from business cards to elaborate packaging designs.

- Customization: Die cutting offers endless possibilities for customization, allowing for unique shapes and creative designs that stand out.

The Art of Die Cutting

Die cutting is not just a mechanical process; it is an art form that enhances the visual appeal of printed materials. By incorporating die-cut elements, designers can add layers of texture, depth, and complexity to their projects, turning simple prints into works of art.

Creative Uses of Die Cutting in Print Finishing

- Window Cuts: Creating openings in packaging or invitations that offer a sneak peek of the contents inside.

- Embossed or Debossed Shapes: Adding raised or recessed designs that give a tactile dimension to the print.

- Custom Shapes: From curved business cards to intricate packaging, custom die cuts can transform the standard into something extraordinary.

Examples of Unique Die Cut Designs

- Pop-Up Cards: Utilizing die cuts to create interactive elements that pop out when the card is opened.

- Layered Brochures: Incorporating die-cut layers to create a multi-dimensional effect that draws attention.

- Custom Packaging: Using die cutting to create packaging that perfectly fits the product while adding an element of surprise and delight for the consumer.

The Role of Die Cutting in Print Finishing

Precision is paramount in die cutting, as even the slightest misalignment can compromise the quality of the final product. A well-executed die cut can make a print project stand out from the competition by adding a touch of sophistication and uniqueness that is hard to achieve with other techniques.

Importance of Precision in Die Cutting

- Professional Finish: Precise die cutting ensures clean edges and accurate shapes, which contribute to a polished and professional appearance.

- Consistency Across Runs: High precision in die cutting guarantees that each piece in a print run matches perfectly, maintaining the integrity of the design.

Cost-Effective Benefits of Die Cutting

- Material Efficiency: Die cutting minimizes waste by optimizing the layout of shapes on the material, leading to cost savings.

- Reduced Labor Costs: Automated die cutting machines can handle large volumes quickly and accurately, reducing the need for manual labor and associated costs.

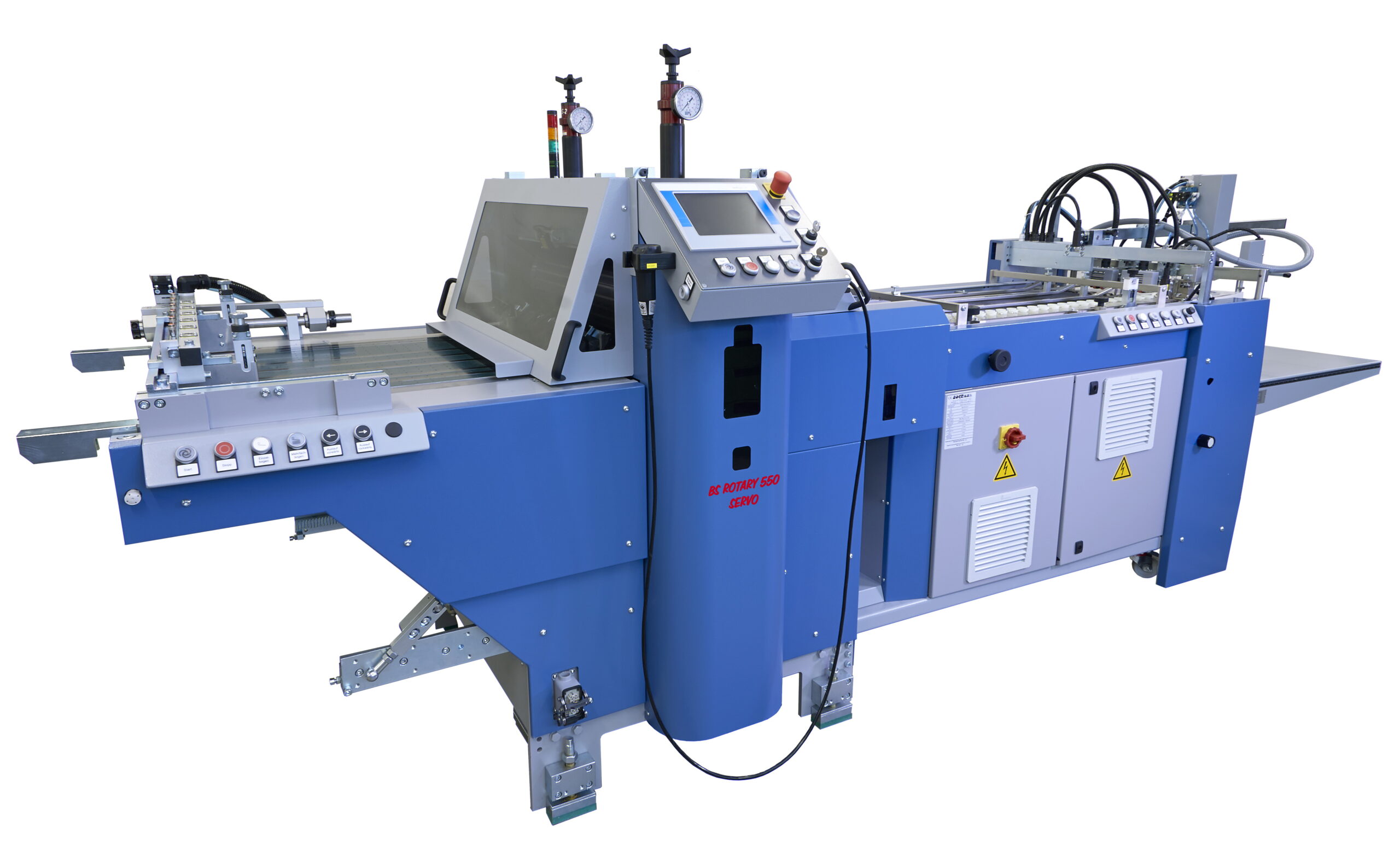

Innovative Machinery: BSR 550 Servo Rotary Diecutter

The BSR 550 Servo Rotary Diecutter is designed specifically for B2 (20″×29″) sheets and is versatile enough for a wide range of products, including: thin or thick sheets, folded products, scored or embossed items, pharmaceutical packaging, labels for various applications, digital prints, mailings, booklet labels, folders, greeting cards, and folding cartons.

The BSR 550 Servo’s rotary process differentiates it from traditional flatbed die cutters by eliminating the need for nicks in the sheet. This “nickless” approach allows for automatic waste stripping, ultimately producing a high-quality product and significantly reducing the need for additional labor in stripping or blanking processes.

Key Features:

- Pile or Pallet Feeder Style: Configured by production requirements to maximize productivity.

- Male/Female Cylinder System: Equipped with two magnetic cylinders that facilitate easy mounting of flexible dies and counter plates for a variety of product.

- Synchronized Die Cylinders: Ensure perfect alignment for any die, including male and female matched sets.

- Magnetic Die Cylinders: Feature a bearer-to-bearer design that simplifies makeready without the need for shims.

- Efficient Die Change: Fast due to pre-installed cylinder register pins and corresponding die register holes, allowing tooling to be reused frequently, even in short-run environments.

- Advanced Waste Removal System: Includes stripper shoes for removing inner scrap holes, such as hanger or sombrero holes.

- Programmable Stripper Module: Enhances waste removal efficiency, and allows for extremely complex jobs to be processed fully.

- Modular Control System: Easily integrates with existing MBO finishing modules, including folders, gluers, web sheeters, and inserters.

The BSR 550 Servo represents the intersection of traditional craftsmanship and modern technology, offering printers and designers innovative solutions to create customized pieces with precision and efficiency.

In conclusion, die cutting is an essential technique in print finishing that offers both aesthetic and functional benefits. From enhancing the visual appeal of printed materials to providing cost-effective production solutions, die cutting plays a critical role in creating high-quality, standout print products. Whether you’re looking to add a unique touch to your next project or achieve precise, consistent results, exploring the possibilities of die cutting can open up a world of creative opportunities.