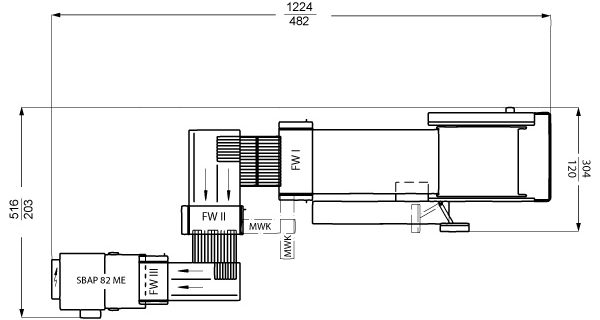

T 1420 Perfection Buckle Folding Unit

Overview:

MBO remains the only remaining manufacturer to produce the XL format folding machines and topping that list is the T1420 capable of processing sheets up to 142cm x 205cm (56″ x 80″) . Their special applications make them unique in the finishing business and are primarily used for long runs of standard, book signature size products. Large sheets can be folded in multiple up fashion creating very high volume output with low labor. With their high speed, large forms and excellent quality, the T 1420 Perfection provides the highest productivity.

Highlights:

- XL format sheet processing for high volumes

- Pallet fed infeeds to eliminate lifting of oversize sheets

- High quality components to ensure accurate folds even at the wide width

- High productivity with running speeds up to 160 m/m (6299 ipm)

Standard Features and Benefits:

- Easy to learn and reliable MC control system

- Up to 4 folding sections to meet the fold pattern requirements of the customer

- Pneumatic lift assist for buckle plate operation

- Manual control of the buckle plates and fold roller settings

- Anti-static lattice table for best control of the paper

- MBO high speed cone guide rail for optimal sheet registration and control

- Standard FP1120/110 palletized feeder to eliminate handling of heavy oversized sheets

- Slitter shaft cassette in units 1 and 2 for fast tooling changes

- Virotec fold rollers for best fold quality

- 4/4/4/2 NIRO, corrosion free, buckle plate configuration for flexibility

- Interface to multiple deliveries and other MBO modules to customize the application for the best ROI

- Low maintenance and noise-free belt drive

-

- Transfer table after first fold section to add control to the product into unit II

Optional Features and Benefits:

- Automation of buckle plates and fold rollers to fit the application

- Multiple fold roller surfaces for best performance with specific stocks and print

- Pre-slitter shaft available for additional perf and score capability

- Transfer tables with ejection capability for bad product detection

- Alternating deflector for increased folding speed on wide products

- Two lane guide systems for increased productivity when 2 up folding

- Slitter shaft tooling assembly kits for presetting scores, perfs and slits and fast makeready

- MBO Sheet Return Device, RFE, to move the delivery of the folder back towards the feeder for less labor

- Connectivity interface to DATAMANAGER

- Gatefold plates for additional fold pattern to meet customer needs

- Noise reducing hoods for an improved working environment